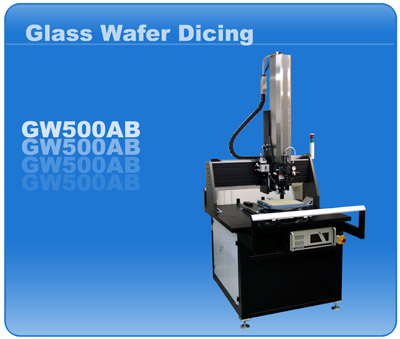

GW500AB: Glass Wafer Dicing

Zero Width Laser Cutting TechnologyTM

The GW500AB is the latest generation of precision ZWLCTTM laser Glass Wafer Dicing system for IR and CF camera windows, micro displays and other demanding applications.

| Parameter | Value |

|---|---|

| Dicing Speed | 1000 mm/sec |

| Glass Wafer Dicing Time | 3.5 min. |

| Surface Area Loss | 0% loss |

| Street Width | 0 |

| HAZ | 0 |

| Surface Temperature |

100° C |

| # of Passes Required | 1 |

| Micro Cracks | none |

| Chipping | none |

| Edge Strength | excellent, 5 times stronger then conventional scribe and brake |

| Glass Wafer Thickness | 0.3 to 0.5 mm |

| Residue | none |

| After-Process Cleaning Requirements | none |

| Clean Room Compatibility | Class 1000 or 10000 |

LASER

- Type Fantom™ sealed CO2 Laser

- allowing modular replacement

WAFER

- Material: Glass 0.3 -0.5 mm thick.

- Wafer size - 12" max.

- Frame: Standard types (5”, 6”, 8” or 12")

- Holding tape: standard low tack

VISION SYSTEM

- Two-level Magnification

- Optical zoom

- Type: Pattern Recognition with

- automatic alignment

MOTION SYSTEM

- 4 axis direct drive servo platform.

- Working area 800 x 800 mm

- Maximum axis speed 2000 mm/s

BREAKING SYSTEM

- Integrated with the scribing head

- Breaking capability - 300 x 300 mm max

Applications Search:

|

Total Matching Applications: 138, Displaying 1 - 3.

Next 3 Applications >> |

|||||||||

|

|||||||||

|

Total Matching Applications: 138, Displaying 1 - 3.

Next 3 Applications >> |

|||||||||