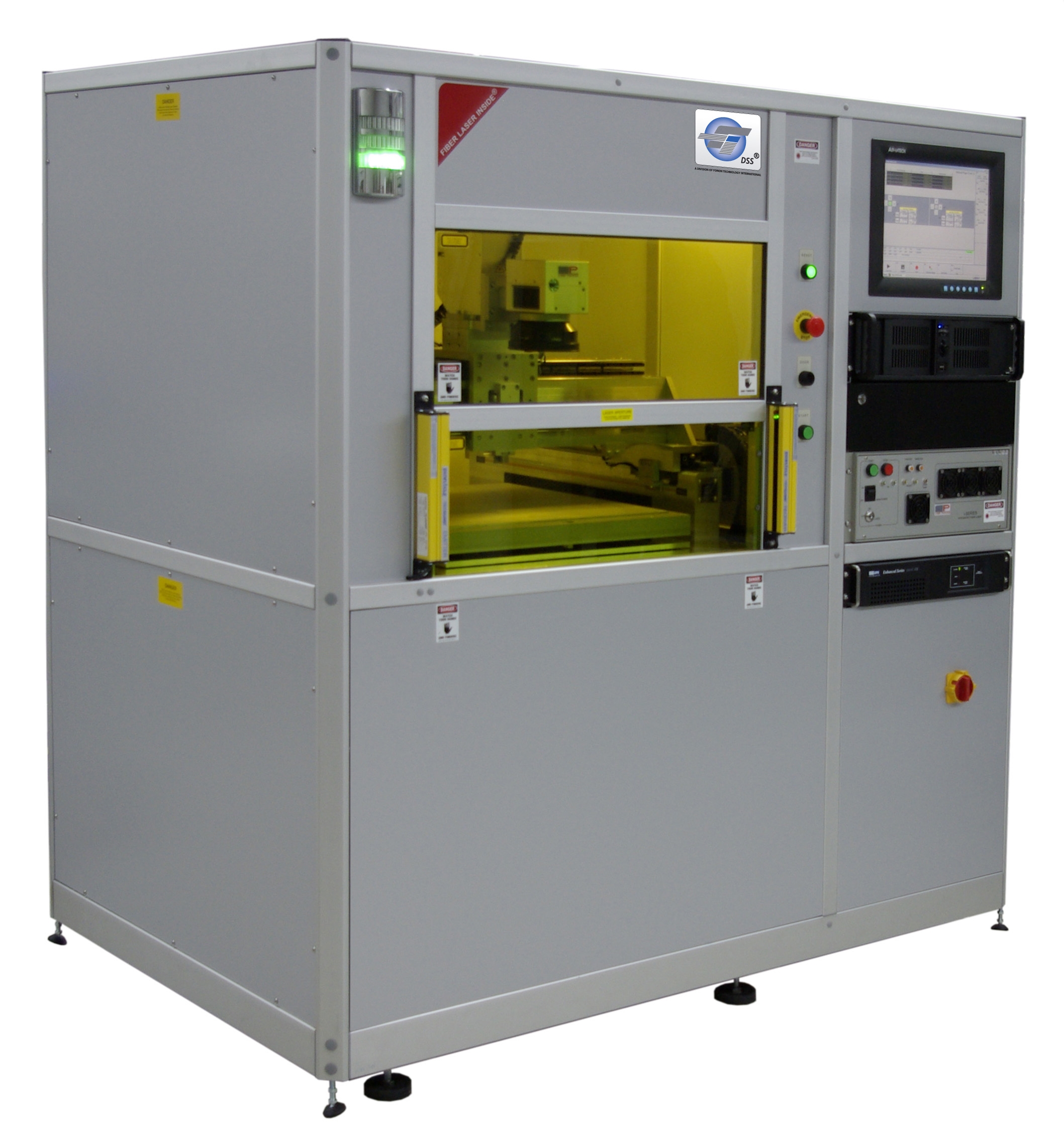

» Semiconductor > Semiconductor Dicing and Scribing Equipment > Silicon Wafer Dicing - BlackStar SW300 Silicon Wafer Dicing - BlackStar SW300BLACKSTAR™ is a Wafer Dicing System utilizing Fantom Width Laser Dicing Technology® (FWLDT®) invented and patented by Fonon Technology and modified to accommodate the requirements of a silicon wafer singulation process without affecting the existent dicing method, processes or procedures. Wafers have the highest value at the dicing stage and the primary focus of a BlackStar™ is to increase the number of dies, yield per wafer, and to maximize throughput while minimizing the HAZ specifically for “power hungry” RF micro devices and low-K wafer substrates. BlackStar™ is an alternative to mechanical saws too damaging and costly for cutting of thin delicate silicon, low-K and complex material wafers.

LASER

WAFER

VISION SYSTEM

MOTION SYSTEM

|

|||||||||||||||||||||||||||||||||||

Semiconductor

Semiconductor Dicing and Scribing Equipment

Silicon Wafer Dicing - BlackStar SW300

Glass Wafer Dicing - GW500AB

Ceramic Scriber

Semiconductor Material Marking Equipment

IC Chip Failure Analysis

Coating Removal

Member of Semiconductor Equipment and Materials International |

Need a Laser Solution:

Call Us at: Highlighted Application:

Contact Us:

| ||||||||||||||||||||||||||||||||||