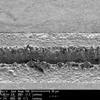

» Generation 8 Laser Glass Cutting Technology Generation 8 Laser Glass Cutting TechnologyFonon Technology International, Inc (www.fonon.com) the world-renowned inventor and manufacturer of equipment based on Zero Width Laser Cutting TechnologyTM (ZWLCTTM; explained in detail below) has announced the latest innovation in laser scribing for the Flat Panel Display (FPD) Industry. The new generation of glass laser cutting equipment - Fantom™ G6 product line based on an F300GL integrated laser module. The mathematical modeling and physical tests lead to a brand new laser beam shape generated directly by the F300GL laser head resulting in full separation of 0.5 – 0.7 mm glass at 500 to 700 mm per second (has been achieved in the company lab on G4 glass for selective applications). The F300GL Integrated CO2 laser system has no need for external beam shaping optical elements and field alignment, and provides virtually maintenance-free, 24/7 operation and a laser replacement procedure requiring less then 30 minutes. Results achieved on G4 glass suggests that the new technology can be used for building industrial-grade laser cutting equipment for Generation 6 and 8 glass panels. The new product will be available as a standalone glass cutting system, as a component for the in-line system from Fonon DSS, and as an OEM package from Laser Photonics– subsidiary of Fonon Technology. As the cost of mechanical scribing machinery increases exponentially with glass panel sizes up to G8 the laser head is no longer a price prohibitive component in the overall equipment cost. "With 40 to 50 glass scribing facilities opening annually in China alone and the emergence of new technology for large format TFT LCD displays (G8 glass size,) the business opportunity for laser cutting equipment in the FPD industry worldwide approaches a level of nearly a quarter billion dollars," states company CEO Demitri Nikitin. Fantom G6™The picture represents a standalone system for scribing TFT LCD panels. Fantom™ G6 product line is based on an F300GL Integrated Glass Scribing Laser Module. This laser module provides a high level of internal part protection and serviceability. It requires no gas and is small enough to mount easily on a machine tool, yet powerful enough for the most challenging FPD applications. “We have accomplished superior results in the Generation 5 & 6 areas, and we are on the verge of incredible breakthroughs for Generation 8”, said Demitri Nikitin, CEO of Fonon Technology. “In addition, new enhancements have been made to our ZWLCTTM making it more efficient with even higher throughput!” When comparing this new technology with the older method of glass cutting, the cost of ZWLCTTM is far below mechanical scribing costs. This change in market ROI makes our ZWLCTTM the best choice since the glass panel industry continues to grow in proportion to panel sizes. “We are currently in negotiations with several companies interested in a joint development and application of our technology for their Generation 8 glass panels. Other companies interested in doing so may contact us for more information at info@fonondss.com” The TechnologyZero Width Laser Cutting TechnologyTM - ZWLCTTM - splits materials on the molecular level with tremendous speed. Additionally there is no material loss, no particles and no chips or other debris associated with conventional scribe and break technology. This is done at tremendous speeds by controlled propagation of a MicroCrack through the subsurface layer of material. The scribe line is formed in such a way that molecules do not leave the surface of the glass, unlike conventional scribe and break technologies. The ZWLCTTM method incorporates controlled heating followed by a cooling of the glass surface. This creates the intermolecular separation of the glass substrate. ZWLCTTM will enhance the FPD separation process in terms of yield, as well as provide a reduction in contamination. ZWLCTTM excels when scribing Generation 6 and 8 panels. Fonon’s patented glass scribing technology surpasses the older mechanical separation technology currently used to cut glass and other brittle materials for the electronic and semiconductor industries. Conventional technology creates vent cracks by stressing the substrate, which in turn creates surface damage and lateral cracks, resulting in particulate generation, and yield loss. It is this loss, plus the purchase cost for mechanical scribing and breaking systems, that has become the significant contributor to the retail cost of modern flat panel displays. ZWLCTTM creates internal tensile forces so great that total separation of display glass is achieved with speeds previously available only for scribing. This process is called full body separation. Full separation speed of 500 – 600 mm/sec has been achieved in our lab on G4 glass for selective applications. This also reduces the known limitations for cross cutting. About the CompanyFonon Technology International, the world-renowned inventor of Zero Width Laser Cutting TechnologyTM (ZWLCTTM), active for 15 years as a global R&D company, has now entered the FPD equipment market. To accomplish this task, Fonon Technology has acquired a number of equipment and laser manufacturing divisions, enabling the company to supply Glass Laser Scribing equipment to the FPD Industry. Fonon has also recently acquired Laser Photonics L.L.C in Orlando Florida, which will manufacture precision equipment using specialized lasers from Laser Photonics. The CEO, Demitri Nikitin announced “We are currently manufacturing world-class equipment for glass scribing (CO2), cutting, ITO removal, and wafer and chip marking, incorporating the new generations of fiber lasers. A primary focus will include semiconductor wafer dicing by supplying systems utilizing the Zero Width Laser Cutting TechnologyTM (ZWLCTTM ) in conjunction with fiber lasers. “Our R&D stage has been validated and Fonon believes that it possesses the best and the most effective technology for display glass and wafer dicing available on the market today”.

|

|||||||

Fonon DSS

Laser Marking & Engraving

Flat Panel Display Systems

Semiconductor

Applications

Technology

About

News

Trade Show Schedule

Member of Semiconductor Equipment and Materials International |

Need a Laser Solution:

Call Us at: Highlighted Application:

Contact Us:

|