Application Newsletter-ITO Removal of Conductive Coatings

Touch Screen Monitors Incorporated Into Automobiles

Due to technological advancements and steadily falling prices of touch screens and flat panel displays, most automobiles will incorporate touch screen interfaces by the year 2009. These touch screen interfaces will encompass controls for heating, air conditioning, entertainment, diagnostics, navigation equipment and trip-computer systems. This technology will add value and character to vehicle interiors, as well as increasing simplicity of operation for all the functions it controls.

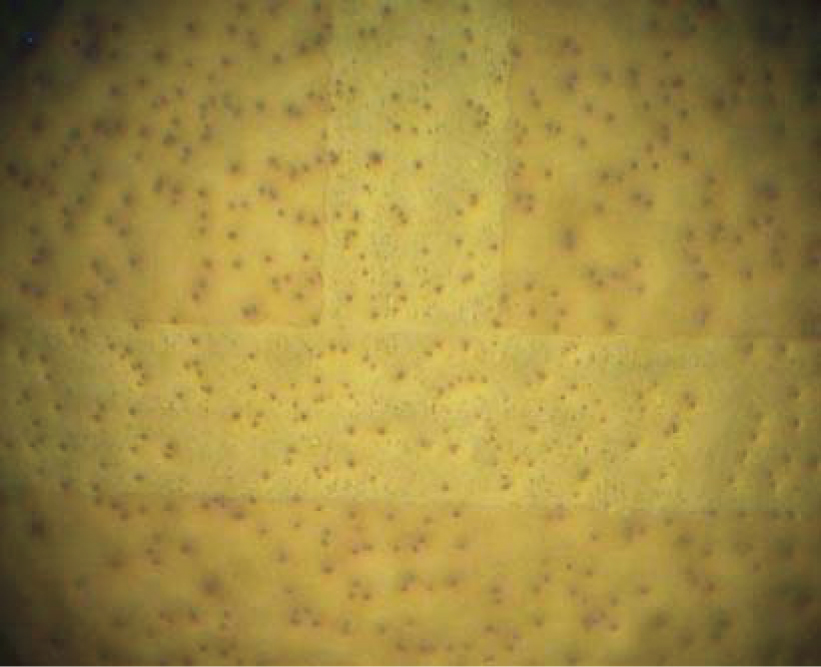

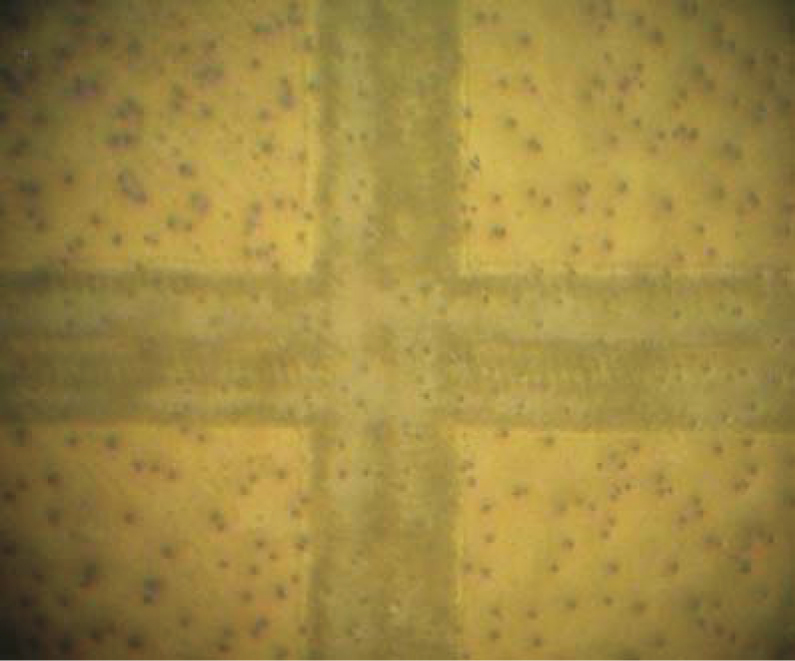

Standard interfaces consist of ITO, CTO, etc. coatings on the screen surface. This coating must go through a removal process to change resistance and allow the interface to properly function. The coating is usually removed with a 5 step chemical process or edging that consumes a large amount of water and is costly and hazardous to the environment. This process can take up to 20 minutes and requires the use of specific utensils. Fonon DSS has developed a system for a unique one step technique that removes the conductive coating using a high intensity laser beam while leaving the substrate intact. The process vaporizes the surface substrate in order to leave the spaces necessary for the proper circuit configuration. The wavelength of laser and energy transmission is ideal for removing the conductive coating without damaging the film or glass unlike other laser processes.

Fonon DSS has developed a comprehensive system, the FL600 ITO Coating Removal System, which uses a X, Y and Z axis motion for unsurpassed accuracy and speed producing the most precise results on the market. The FL600 has the best accuracy available today creating extremely high quality laser machining results. The system is a safe, low cost, quick method to remove ITO from glass typically used in flat panel displays, liquid crystal displays and touch screen displays.

Benefits:

- Highest ITO removal speed in the industry at speeds of up to 12m/s for glass and plastic substrates

- Maximum substrate size of up to Generation 8 glass panels

- Unlimited component size

- Environmentally friendly process

Fonon DSS (Display & Semiconductor Systems) is a division of Fonon Technology International, providing state-of-the-art Laser Scribing, Laser Dicing and Fiber Laser Marking solutions to customers in the FPD, Semiconductor and Electronics industries throughout the world. To learn more about Fonon DSS technology and for all product features and benefits, visit www.Fonondss.com or call our office at 407-829-2613.

To remove your name from our mailing list, please click here. Questions or comments? Email us at info@fonondss.com or call 407-804-1000. Copyright 2026 Fonon DSS. All Rights Reserved.

Fonon DSS products and product names are either trademarks or registered trademarks of Fonon DSS. All other trademarks or registered trademarks are the property of their respective intellectual property owners.