Cutting Costs With Zero Width Technology

Zero Width Laser Cutting Technology™ (ZWLCT™) is a major discovery, from Fonon Technology International, resulting in radical change on the process of cutting glass and other brittle materials. ZWLCT™ has applications in the electronic, flat panel display, solar and semiconductor industries. The METHOD splits materials on the molecular level at tremendous speed with no material loss or chips and other debris.

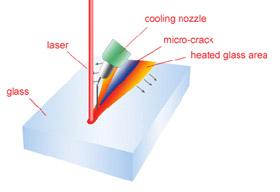

classic and most prevalent glass separation technology. This is a process that involves the mechanical scribing of a vent in the upper surface of the glass. This is usually accomplished with a diamond or tungsten carbide wheel. The result of this is a score line, which is a combination of controlled damage to the surface, lateral cracks, and when the parameters are well controlled, a vent crack is created. The ZWLCT™ technique generates a MicroCrack™ without substrate contact. It is done at tremendous speeds by controlled propagation of a MicroCrack™ through the subsurface layer of material. The ZWLCT™ METHOD incorporates cooling of the glass surface, following controlled heating, with the correct power density profile, creating the intermolecular

classic and most prevalent glass separation technology. This is a process that involves the mechanical scribing of a vent in the upper surface of the glass. This is usually accomplished with a diamond or tungsten carbide wheel. The result of this is a score line, which is a combination of controlled damage to the surface, lateral cracks, and when the parameters are well controlled, a vent crack is created. The ZWLCT™ technique generates a MicroCrack™ without substrate contact. It is done at tremendous speeds by controlled propagation of a MicroCrack™ through the subsurface layer of material. The ZWLCT™ METHOD incorporates cooling of the glass surface, following controlled heating, with the correct power density profile, creating the intermolecular  separation of the glass substrate to a certain depth.

separation of the glass substrate to a certain depth.  Fonon DSS, is a division of Fonon Technology International, the world renowned inventor and manufacturer of Zero Width Laser Cutting Technology™. Fonon DSS focuses on the semiconductor and flat panel display industries utilizing the patented Zero Width Laser Cutting Technology™ (ZWLCT™) to create products with the highest level of precision.

Fonon DSS, is a division of Fonon Technology International, the world renowned inventor and manufacturer of Zero Width Laser Cutting Technology™. Fonon DSS focuses on the semiconductor and flat panel display industries utilizing the patented Zero Width Laser Cutting Technology™ (ZWLCT™) to create products with the highest level of precision.To remove your name from our mailing list, please click here. Questions or comments? Email us at info@fonondss.com or call 407-804-1000. Copyright 2026 Fonon DSS. All Rights Reserved.

Fonon DSS products and product names are either trademarks or registered trademarks of Fonon DSS. All other trademarks or registered trademarks are the property of their respective intellectual property owners.