Coating Removal Made Easy with Fiber Laser Technology

Indium Tin Oxide (ITO) is a transparent conductive material very commonly used for electrodes in the Flat Panel Display industry as well as the fast growing Solar Industry. Currently, the most common process for the removal of ITO is chemical etching, a process that can take up to twenty minutes to complete and requires the use of specially designed stencils. In contrast, Fiber Laser Technology is a proven process, which performs an ablation using a high intensity laser beam to vaporize the ITO directly from the surface substrate in order to leave the spaces necessary for the proper circuit configuration.

Fiber Laser Ablation is a One Step Process.

In comparison to traditional wet chemistry removal, with the FL600™ no chemicals are used, meaning no pollution or chemical waste disposal this significantly reduces operating costs.

The FL600™ Fiber Laser ITO Ablation System is a safe, low cost, quick method to remove ITO from glass typically used in flat panel displays, liquid crystal displays, touch screen displays and solar panel manufacturing. The FL600™ is capable of direct fiber laser patterning on indium tin oxide (ITO), TCO, TO, anti-reflective coatings on glass and polyethylene terephtalate (PET) plastic film used in the FPD industry, automotive windshields and rear view mirrors, architectural windows, photovoltaic cells, solar panels, and semiconductor applications. The FL600™ is extremely stable and maintains steady parameters across the various substrates, this increases productivity and reduces downtime. Using our FiberScan C3™ graphical-based laser programming software, users can easily produce ITO ablation programs with minimal learning curve.

|

|

|

|

|

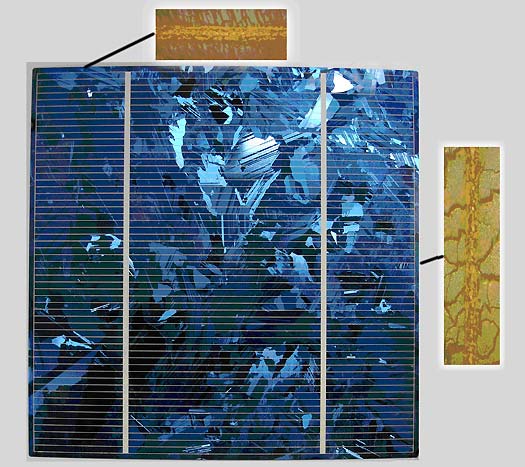

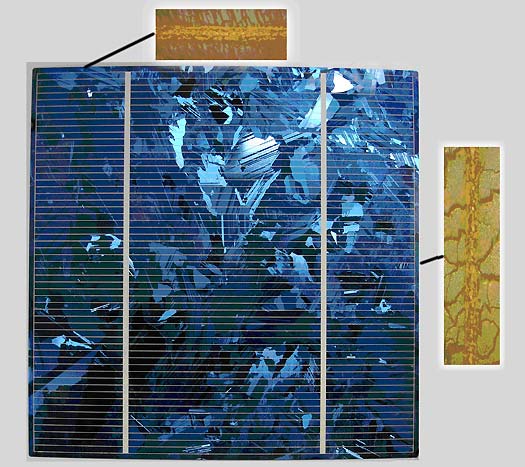

Solar Panel ITO Removal

|

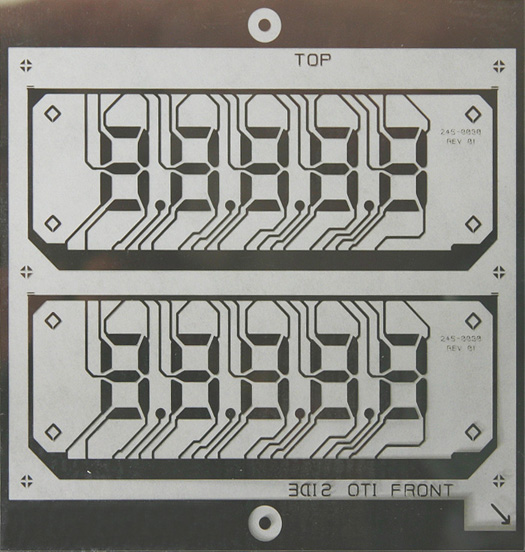

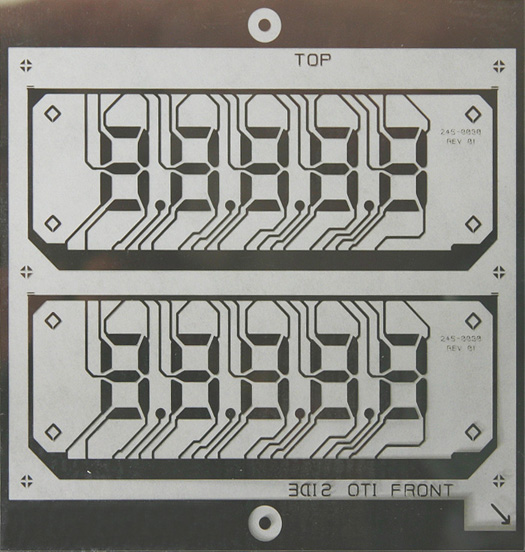

TN/STN Display

|

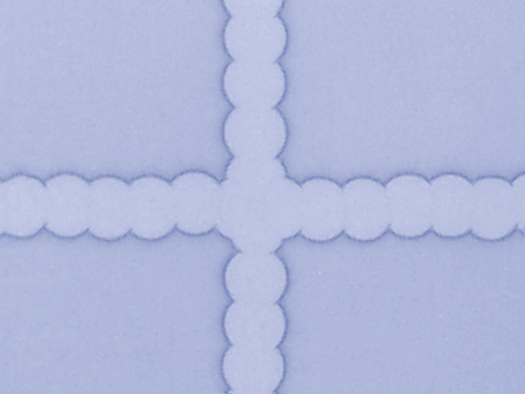

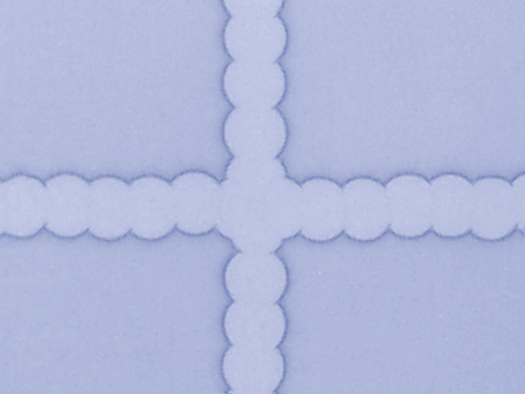

ITO Removal on Glass

|

Fonon DSS (Display & Semiconductor Systems) is a division of Fonon Technology International, the world renowned inventor and manufacturer of Zero Width Laser Cutting Technology™. Fonon DSS focuses on the semiconductor and flat panel display industries utilizing the patented Zero Width Laser Cutting Technology7trade; to create products with the highest level of precision. Fonon DSS (Display & Semiconductor Systems) is a division of Fonon Technology International, the world renowned inventor and manufacturer of Zero Width Laser Cutting Technology™. Fonon DSS focuses on the semiconductor and flat panel display industries utilizing the patented Zero Width Laser Cutting Technology7trade; to create products with the highest level of precision.

|

Fonon DSS (Display & Semiconductor Systems) is a division of Fonon Technology International, the world renowned inventor and manufacturer of Zero Width Laser Cutting Technology™. Fonon DSS focuses on the semiconductor and flat panel display industries utilizing the patented Zero Width Laser Cutting Technology7trade; to create products with the highest level of precision.

Fonon DSS (Display & Semiconductor Systems) is a division of Fonon Technology International, the world renowned inventor and manufacturer of Zero Width Laser Cutting Technology™. Fonon DSS focuses on the semiconductor and flat panel display industries utilizing the patented Zero Width Laser Cutting Technology7trade; to create products with the highest level of precision.